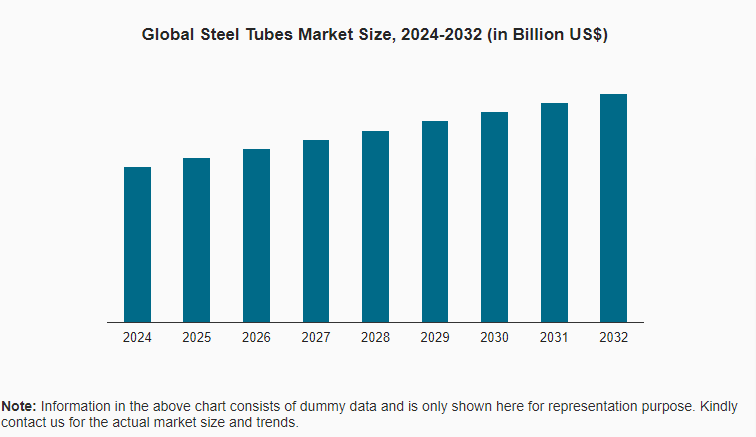

Market Growth and Size: The steel tubes market is witnessing stable growth, driven by global industrialization and urbanization. The market’s size reflects a robust and growing industry, underpinned by strong demand in key sectors such as construction, automotive, and oil and gas.

Major Market Drivers: The rapid pace of industrialization, especially in emerging economies, and the growing demand in the construction and automotive sectors are positively influencing the market. The oil and gas sector also remains a major consumer, necessitating steel tubes for exploration and transportation activities.

Technological Advancements: Innovations in manufacturing processes, such as electric resistance welding and seamless tube processing are enhancing the quality and range of steel tube products. The adoption of digital technologies and automation in manufacturing is also optimizing production costs and time.

Industry Applications: Steel tubes are extensively used in various industries including construction for structural support, automotive for component manufacturing, and oil and gas for pipelines. Their versatility and strength make them ideal for diverse applications across numerous sectors.

Key Market Trends: The emerging trend towards sustainable and socially responsible manufacturing, with an increasing focus on using recycled materials, is favoring the market. Additionally, the demand for lightweight and high-strength steel tubes is growing, especially in sectors including automotive to improve fuel efficiency.

Geographical Trends: Asia-Pacific dominates the market, driven by infrastructure development and industrialization in countries such as China and India. North America and Europe also hold significant shares, with a focus on high-quality and sustainable products, while emerging economies present growth opportunities.

Competitive Landscape: The market is characterized by intense competition with key players engaging in strategic initiatives including mergers, acquisitions, and research and development to innovate and expand their market presence.

Challenges and Opportunities: Regulatory changes and market volatility pose challenges, but these also open opportunities for innovation in product development. There is a growing opportunity in emerging markets where steel tube penetration is still evolving, offering potential for expansion.

Steel Tubes Market Trends:

Global Industrial Growth and Urbanization The steel tubes market is significantly driven by the rapid pace of industrial growth and urbanization worldwide. The expansion of industries such as construction, automotive, and oil and gas is escalating the demand for steel tubes, given their strength, durability, and versatility. In the construction sector, steel tubes are essential for structural support and architectural applications, while in the automotive industry, they are crucial for manufacturing various components. Additionally, the rise in urbanization has led to increased infrastructure development, particularly in emerging economies, where large-scale construction projects are underway. These projects require substantial quantities of steel tubes for building frameworks, piping systems, and other structural elements. The ongoing urbanization trend, especially in Asia-Pacific and Middle Eastern countries, is positively influencing the market.

Technological Advancements in Manufacturing

Technological advancements in the manufacturing processes of steel tubes are pivotal in driving the market growth. Innovations in production techniques, such as electric resistance welding and seamless tube processing, have enhanced the efficiency, quality, and range of steel tube products. These advancements are enabling manufacturers to produce tubes with greater precision, varied sizes, and improved properties such as enhanced strength and corrosion resistance. This development is particularly significant in industries that demand high-specification products, such as aerospace, high-pressure applications, and high-temperature environments. Moreover, the integration of digital technologies and automation in manufacturing processes is optimizing production costs and time, leading to more competitive pricing and availability of products. As manufacturers continue to invest in research and development, the market is benefiting from these technological innovations, ensuring the supply of superior and customized products for diverse applications.

Environmental Regulations and Sustainability Initiatives

Environmental concerns and the implementation of stringent regulations regarding emissions and energy consumption have become major factors influencing the steel tubes market. The steel industry is under increasing pressure to reduce its carbon footprint and improve sustainability in manufacturing processes. This scenario is prompting steel tube manufacturers to adopt eco-friendly practices, such as utilizing recycled materials and enhancing energy efficiency in production. In addition, there is a growing demand for lightweight and high-strength steel tubes in various industries to improve energy efficiency and reduce environmental impact. For instance, in the automotive sector, lightweight steel tubes contribute to lower vehicle weight, thereby enhancing fuel efficiency and reducing emissions. These environmental and sustainability initiatives comply with regulatory standards and resonate with the evolving preferences of consumers and industries toward more sustainable products. This shift is influencing market dynamics, driving innovation, and the adoption of green practices in the steel tube industry.

Steel Tubes Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2024-2032. Our report has categorized the market based on product type, material type and end use industry. orized the market based on product type, material type and end use industry.

Seamless steel tubes accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the product type. This includes seamless steel tubes and welded steel tubes. According to the report, seamless steel tubes represented the largest segment.

As the largest segment in the steel tubes market, seamless steel tubes are highly sought after for their strength, uniformity, and high tolerance levels. This segment encompasses tubes manufactured without a welded seam, manufactured through a process that involves extruding the metal into the desired shape. They are particularly preferred in applications where strength and reliability are paramount, such as in high-pressure gas or oil pipelines, in the aerospace industry, and automotive applications. Their ability to withstand high pressures and temperatures without the risk of seam failures makes them ideal for critical applications. The demand for seamless steel tubes is also driven by industries requiring precise dimensions and quality, such as hydraulic systems and various manufacturing machinery.

Welded steel tubes, while smaller in market share compared to seamless tubes, hold significant importance due to their cost-effectiveness and versatility. This segment includes tubes manufactured by welding the edges of steel strips or coils, often using Electric Resistance Welding (ERW) or Submerged Arc Welding (SAW). These tubes are widely used in lower-pressure applications, such as in the construction industry for structural supports, in the automotive sector for non-critical components, and in general engineering applications. Additionally, advances in welding technology are improving the quality and reliability of welded tubes, expanding their applicability. The versatility in terms of size and shape, along with improvements in manufacturing processes, underpins the steady demand for welded steel tubes in various industrial and commercial applications.

Carbon steel holds the largest share in the industry

A detailed breakup and analysis of the market based on the material type have also been provided in the report. This includes carbon steel, stainless steel, alloy steel, and others. According to the report, carbon steel accounted for the largest market share.

As the largest segment in the steel tubes market, carbon steel tubes are predominantly favored for their versatility and cost-effectiveness. Carbon steel, an alloy of iron and carbon, offers a balance of strength, malleability, and weldability, making it suitable for a wide range of applications. This segment caters to industries such as construction, where steel tubes are used for structural purposes, and in the manufacturing of machinery where strength and durability are vital. The automotive industry also extensively uses carbon steel tubes for various components. The relatively low cost of carbon steel compared to other materials is a significant factor contributing to its dominant market position.

Stainless steel tubes represent a significant segment of the market, known for their corrosion resistance and aesthetic appeal. This material is an alloy of iron, chromium, nickel, and other elements, which gives it its corrosion-resistant properties. Stainless steel tubes are essential in environments where resistance to corrosion and staining is crucial, such as in chemical processing, food and beverage production, and medical equipment. Their non-reactive nature makes them ideal for sanitary applications as well. While more expensive than carbon steel, the durability and low maintenance requirements of stainless-steel tubes make them a cost-effective choice over their lifespan.

Alloy steel tubes, manufactured by combining carbon steel with various alloying elements such as chromium, molybdenum, nickel, and vanadium, are valued for their specific properties such as enhanced strength, durability, and resistance to wear and tear. This segment caters to specialized applications that require higher performance standards, such as in the power generation sector, aerospace, and high-pressure applications in the oil and gas industry. The addition of alloying elements allows for the creation of steel tubes with tailored properties, suitable for environments that involve extreme temperatures, pressures, or corrosive substances.

Oil and gas represents the leading market segment

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes oil and gas, petrochemicals, infrastructure and construction, automotive, water treatment and sewage, and others. According to the report, oil and gas represented the largest segment.

The oil and gas industry is the largest segment in the steel tubes market, primarily due to the extensive use of these tubes in exploration, drilling, and transportation activities. Steel tubes in this sector are crucial for constructing pipelines, drilling rigs, and other infrastructure necessary for the extraction and transportation of oil and natural gas. These tubes are preferred for their strength, durability, and resistance to harsh environments, including corrosive substances and extreme pressures and temperatures encountered in oil and gas extraction and processing. Seamless steel tubes, in particular, are in high demand in this segment due to their ability to withstand the high stresses of drilling operations and the transport of fluids under high pressure.

In the petrochemical industry, steel tubes play a vital role in the transportation and processing of chemicals. This segment requires tubes that can resist corrosive substances and maintain integrity under high temperatures and pressures. Steel tubes used in petrochemical plants are integral to the construction of refineries, chemical reactors, and storage vessels.

The infrastructure and construction sector heavily relies on steel tubes for various applications, including building frameworks, scaffolding, and architectural elements. Steel tubes in this segment are valued for their strength, flexibility, and ease of installation, making them suitable for both structural and aesthetic purposes. The growth in urbanization and the consequent rise in construction activities, particularly in emerging economies, significantly contribute to the demand in this sector.

In the automotive industry, steel tubes are used for manufacturing various components, including chassis, exhaust systems, and suspension parts. This segment demands steel tubes that combine lightweight characteristics with strength and durability, contributing to vehicle efficiency and safety. The ongoing evolution in automotive design and the increasing focus on fuel efficiency and emission control continue to drive innovation and demand for specialized steel tubes in this industry.

Asia Pacific leads the market, accounting for the largest steel tubes market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Asia Pacific, Europe, North America, Middle East and Africa, and Latin America. According to the report, Asia Pacific accounted for the largest market share.

The Asia Pacific region is the largest segment in the steel tubes market, primarily driven by rapid industrialization and urbanization in major economies such as China, India, and Japan. This region’s growth is bolstered by the expansive development in sectors like construction, automotive, and oil and gas. The high demand for infrastructure development, coupled with the increasing focus on manufacturing and industrial expansion, significantly contributes to the market. Governments in the region are investing heavily in infrastructure projects, which include transportation networks, urban development, and energy projects, further fueling the demand for steel tubes.

Europe holds a significant share of the global steel tubes market, characterized by advanced manufacturing technologies and stringent environmental regulations. The region’s focus on sustainable and high-quality products drives the demand for specialized steel tubes, especially in the automotive, construction, and energy sectors. European countries are known for their robust automotive industry, requiring high-grade steel tubes for manufacturing various vehicle components. Additionally, the region’s commitment to renewable energy and modern infrastructure projects necessitates the use of steel tubes that meet high standards of quality and environmental sustainability.

The North American market, encompassing the United States and Canada, is a major player in the industry. The market is driven by the well-established oil and gas sector, particularly in the U.S., where steel tubes are essential for exploration and transportation activities. Additionally, the region’s automotive industry, which is transforming with a focus on electric and fuel-efficient vehicles, contributes to the demand for high-quality steel tubes.

The market in the Middle East and Africa is influenced largely by the oil and gas sector, especially in countries such as Saudi Arabia, UAE, and Nigeria. The demand for steel tubes in this region is primarily driven by the need for pipelines and infrastructure in the oil and gas industry. Moreover, the Middle East is witnessing significant investments in infrastructure and construction projects, including smart city developments and transportation networks, which are further stimulating the demand for steel tubes.

Latin America’s market is shaped by the region’s growing industrial and construction sectors, particularly in countries. The demand in this region is supported by the development of transportation infrastructure, urban housing projects, and energy exploration activities. Latin America’s agricultural sector, which requires robust machinery and equipment, also contributes to the demand for steel tubes.

Leading Key Players in the Steel Tubes Industry:

Key players in the market are actively engaging in various strategic initiatives to maintain and enhance their market positions. This includes investments in research and development to innovate and improve the quality and range of their products, particularly focusing on developing high-strength, lightweight, and corrosion-resistant steel tubes. Many are also expanding their manufacturing capabilities and global presence through strategic mergers, acquisitions, and partnerships, allowing them to tap into new markets and diversify their product offerings. Additionally, there is a notable emphasis on sustainability and environmentally friendly manufacturing processes, aligning with global trends and regulatory requirements. These players are not only focusing on operational efficiency but also on meeting the evolving demands of industries such as automotive, construction, and energy, which are the primary consumers of steel tubes.

The report has also provided a comprehensive analysis of the competitive landscape in the global steel tubes market.